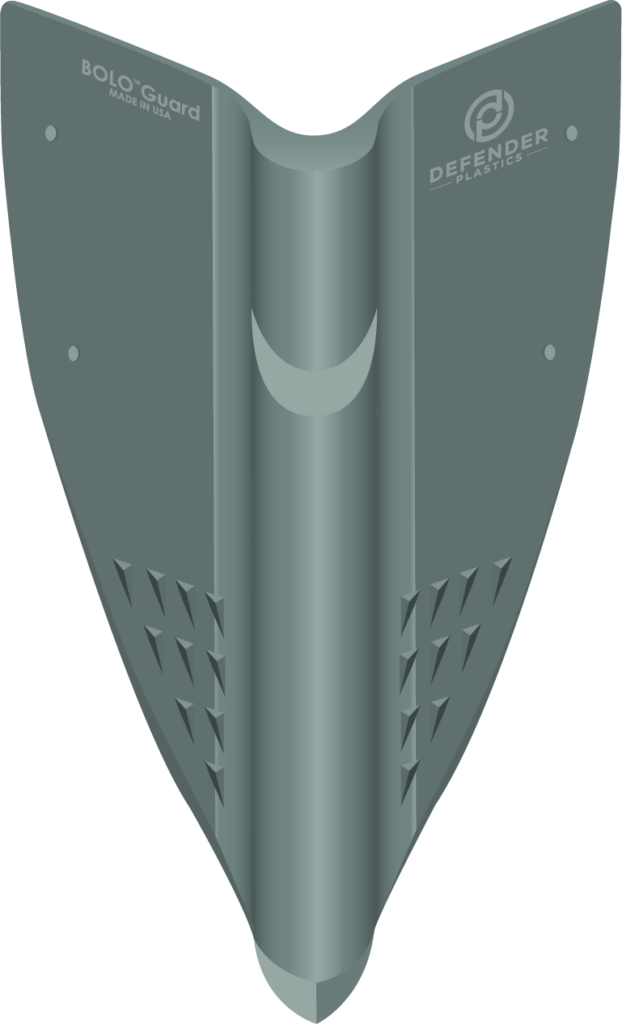

BOLO™ Guard

Why do I need a BOLO Guard?

What have you got to lose if you pass on BOLO™ Guard?

Apparently, a lot.

We get it. Installing BOLO™ Guard on every utility box – yes, even and especially the undamaged ones – seems like a daunting task. Considering the long-term impact on budget, resources, safety risk, and reliability, installing BOLO™ Guard is a no-brainer.

Wasted Time

Commonly-used patching systems can take up to 30 minutes per corner. BOLO™ Guard takes less than 60-seconds to install per corner.

Increased Cost

Patching systems cost upwards of $70-$155. BOLO™ Guard costs $29.99.

Mis-used Resources

Patching kits contain multiple elements and a 10+ step process, often requiring an experienced technician. Using a deadblow hammer, BOLO™ Guard can be installed by anyone.

Lack of Reliability

Patching systems are not long-term solutions to damage. BOLO™ Guard prevents damage.

Questions on BOLO™ Guard? No problem!

Each guard is $29.99. Though not required for proper installation, some utility companies may want to add self-drilling screws, fender push pins, or a glue to further secure the guard in place. Factor in an additional $1-$5 per guard if these extras are desired.

BOLO™ Guard is 100% Made in the USA – from engineering and design, to the sourcing of the plastic resin, to the manufacturing, sales and distribution.

Yes, the green resin blend used to create the BOLO™ Guard was constructed with a factory sample order as a direct match to the Munsell Electric Power Industry Standard #7GY3.29/1.5.

The BOLO™ Guard has been tested to the power industry’s recommended standard of ASTM G154. As with most products constantly exposed to the sun, fading will eventually happen, but it meets the same requirements as the rest of the industry’s outdoor UV test requirements.

We carry a significant inventory of over 10,000 units of each product. Our channel partners ship out of their stock the day following receipt of your PO. Tracking can be available within 24 hours of shipment. For orders above 10,000 units, our lead time will be 4 weeks. We can manufacture 2,500 units per day.

Call us. Email us. We will review any application or equipment you want protected. We have a team of development engineers who understand the capabilities and limitations of injection molding and custom resins. We’d love to work with you!

The flange version is most commonly used for single-phase transformer boxpads, or boxpads that typically have less total exposure above ground. It provides additional protection on that topline exterior edge of the corner that those boxpads often need in the residential areas they serve.

The no-flange version was designed for those applications where more boxpad is exposed above grade, like a sectionalizing cabinet. The guard only needs to be exposed above grade by 4-6” to protect from a mower deck.

Flange vs No-Flange Options

Shape View

Top View

Flange Version

No-Flange Version

Shape View

Top View

How BOLO Guards work for you.

Saves Money

Affordable, less expensive than replacing the entire structure

Saves Time

Reduces times spent on repairs and replacements

Easy to Install

60 seconds, no special tools or technicians needed

Durable

Impact & abrasion resistant, UV stabilized, non-metallic